What is the Dominga Project?

We are a seaport mining project located in the Region of Coquimbo, with mineral deposit situated 16 km northwest of the town of La Higuera, where the plant, the two pits, the waste dump and the tailings thickened deposit shall be set.

The plant will be connected to the seaport boarding terminal through three 26-kilometer underground pipelines that will carry water and iron.

The seaport shipping terminal will be located in the town of Totoralillo Norte, where the Commune´s first mining seaport was built, and where the new facilities for the collection, filtration and shipment of iron concentrate through closed conveyor belts system will be and mobile loaders will carry the iron concentrate directly to the ship’s holds, avoiding material leaks.

A desalination plant that will allow us to operate with seawater in all our processes, in addition to delivering 5 Liters per second of desalinated water, available to be processed to drinking water for the Commune of La Higuera.

Dominga´s Timeline

Our commitment to the environment

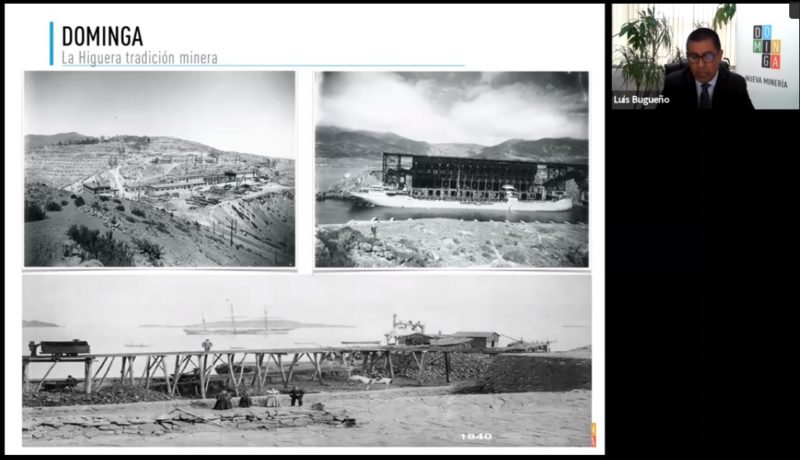

Mining Tradition

By the beginning of the 19th century, workers, adventurers and investors were already extracting minerals from the “Norte Chico“, or the little north -the former provinces of Atacama and Coquimbo-.

The mine known as “El Tofo”, located at the commune of La Higueraand exploited since 1870, was the most important iron mine of its time, operating the first electric railroad in South America to transport the iron to its seaport.

The prosperity brought by mining activity in this area was such, that the construction of the country´s first railway, in 1851, was financed with regional capital. This railway linked the city of Copiapó with the new seaport of Caldera.

The Dominga project salvages a long established tradition in the region, linked to its territorial identity and anchored in mining heritage, rescuing its historical value and giving it a renewed meaning.

Document yourself

- Environmental Impact Study

- Framework Agreement

- Environmental Assessment

- Environmental Court

- Downloadable

Jot Down

Direct new jobs during construction.

Direct new jobs during operation.

Indirect new jobs during construction.

Indirect new jobs during operation.

Get Informed

During the 22 years of projected operation of two open-pit mines located in the La Higuera Commune, 16 km northeast of communal capital, we expect to extract 12 million tons per year of High-Grade iron concentrate – contributing with the necessary reduction of CO2 emissions in the steel industry – and 150 thousand tons per year of copper concentrate – cooperating with electromobility.

We will activate the zone and the Region´s productive sector. During the construction phase we plan to create 10,000 direct jobs and 25,000 indirect jobs. During the stage of operation, we expect the creation of 1,500 direct jobs and 4,000 indirect jobs.

These jobs, which are preferentially destined to regional workers and companies, will revitalize the communal, regional and national economy.

In addition, we have a robust social proposal that acknowledges the right of the Commune´s population to benefit from the mineral resources. In this context, the Company has signed a Framework Agreement along with over 1,600 neighbors, where we pledge to share the profits with the entire community through the transfer of funds to finance those projects that the community considers appropriate according to their social and economic value.

We will use seawater in all our processes. To this end, we will install a desalination plant with a collection container situated 750 meters from the coast and 20 meters below ground, where the presence of plankton is significantly lower. The discharge pipe has a 44m diffuser system, located 720m from the coast, with 12 jets spaced at 4 m with a dilution capacity of 95% in a range of 4 m.

On the contrary, part of the desalinated water produced will be delivered to the Commune of La Higuera: 5 liters per second of desalinated water, available to be processed as drinking water.

To ensure its normal flow, any fresh water we might find in layer deposits will be captured and returned to its natural course, thus maintaining the natural evolution of Los Choros Aquifer.

Our proposed modern tailings management system reduces the likelihood of leakage into groundwater or through rainwater.

The thickened tailings deposit system considers reducing the moisture content in the material to be deposited, thus facilitating its compaction and drying, minimizing the risk of acidic water generation.

In addition, and as a safety precaution, the thickened tailings deposit will be located over 40 kilometers from protected areas beyond a mountain range, upstream and across from the local highway.

Our seaport and water desalination plant will be located 30 kilometers away, in a straight line, from the Humboldt Penguin National Reserve, even further than the Cruz Grande mining port of the Pacific Mining Company (CAP), already granted approval by the same institution that assessed Dominga.

There are already some 1,600 ships currently circulating, along the coasts of the Coquimbo Region a year, just a few kilometers from the Humboldt Penguin National Reserve (approx. 5 km).

Our project estimates traffic flow of 56 vessels per year, at a speed of 18 km per hour and more than 20 km away from the Reserve.

We have a deep commitment to the environment, therefore we have worked on a strong, binding and independent proposal, which provides scientific knowledge of current and future conditions of marine biodiversity and thus adjusts all our operations and those of any company, to the goal of environment protection.

Some of our numbers

Million US dollars of investment.

Projected years of operation.

Formal processes for active citizen involvement and participation.

Signatures from neighbors within the Framework Agreement.

AVISO IMPORTANTE

ESTAFA VÍA CORREO ELECTRÓNICO

Circula en redes sociales una información falsa sobre ofertas laborales para trabajar en Andes Iron SpA. Al respecto, queremos aclarar que:

- Andes Iron SpA no solicita ni solicitará ningún pago para postular a una vacante laboral en nuestra empresa.

- Informamos a las personas para que tomen los resguardos necesarios y no sean víctimas de este tipo de estafas.

- Todos los procesos de selección serán notificados de manera oportuna a través de nuestros canales corporativos formales.

Difunde y comparte, es tarea de todos cuidarnos.

Asuntos Corporativos Andes Iron.